Unlocking the Future of Industry XR and Digital Twins in Manufacturing

- viroinnovation

- Feb 20

- 3 min read

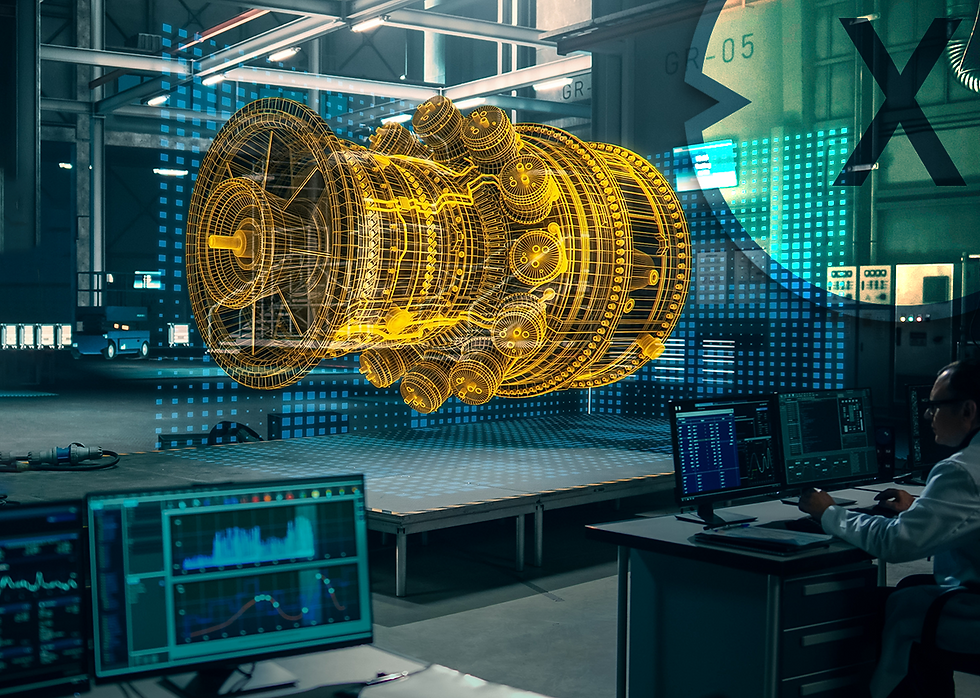

The Role of Digital Twins in Manufacturing

The fourth industrial revolution or Industry 4.0 relies on digital twins. These virtual tools allow technicians to visualize products and factory processes, collaborate with team members worldwide, and receive executive sign-off before a physical product exists. Digital twins are a crucial component of modern manufacturing processes.

What Are Digital Twins in Manufacturing

Businesses use digital twins in construction manufacturing factory planning and more to replicate real-world buildings heavy equipment and products in a virtual environment. With XR headsets and controls, workers get a life-like view of objects at a one-to-one scale and understand their relationship to product design.

Teams interact with virtual objects test features and processes and make decisions faster and at lower costs. Some digital twins are so detailed that users point to a single bolt within a product and instantly see who made it how much it cost its specifications manuals and more. Organizations use XR-enabled digital twins to enhance

Prototyping

Product design

Factory planning

Project planning

Human factors and ergonomics

Critical skills training

Familiarization and safety training

Warehousing

Sales and marketing

Simulation

Maintenance

Renovation and decommissioning

Speed Up Product Development

Product development is complex and time-consuming requiring coordination across multiple teams to research and develop prototypes through multiple revisions. Many of these teams are in different cities or countries requiring extensive travel for product presentations and executive sign-offs.

By integrating digital twins into XR environments businesses streamline the entire product development chain reducing prototyping and decision-making time.

John Maxfield business development director at VR solution provider Virtalis considers digital twins as essential as video conferencing software

Businesses need to be able to effortlessly collaborate not just in the same room but in a distributed environment as well Digital twins allow teams to join a virtual workspace and have dynamic conversations just like they do with Teams or Zoom today

Virtalis works with major manufacturing companies including Ford Motors Siemens Rolls-Royce and Airbus. Their biggest success with digital twins is in collaborative design review leading to

45 percent faster project times

40 percent reduction in project costs

30 percent decrease in product development time

67 percent increase in design sign-offs using digital twins

Enhance Training Outcomes

Building real-world manufacturing training scenarios is expensive time-consuming and difficult to scale. Digital twins provide

Greater flexibility

Improved knowledge retention

Faster training development

Safe and immersive learning environments

Typical training scenarios include

Training teams on new assembly or manufacturing processes

Practicing maintenance tasks and testing new procedures

Training customers on standard operating procedures for large equipment

Simulating emergency situations and hazardous environments

Maxfield highlights the training impact seen by Virtalis clients

78 percent improved retention of assembly and maintenance processes

40 percent faster knowledge acquisition

40 percent reduction in training costs

30 percent reduction in training time

Optimize Factory Layouts and Worker Ergonomics

Maxfield notes that digital twin technology for factory layout planning is one of the fastest-growing use cases for XR

With digital twins we create a virtual model of an entire factory to test and validate layouts material flows manufacturing cells and process efficiencies all without disrupting any physical operations

Beyond improving factory operations digital twins play a major role in worker ergonomics XR users

Visualize ergonomic risks in real-time

Simulate physical strain based on worker height and reach

Optimize workstation and tool placement to reduce injuries

With digital twin simulations manufacturing plants report

80 percent reduction in reported issues

25 percent reduction in time to adapt work cells

50 percent faster product time to market

70 percent reduction in production line injuries

Comments